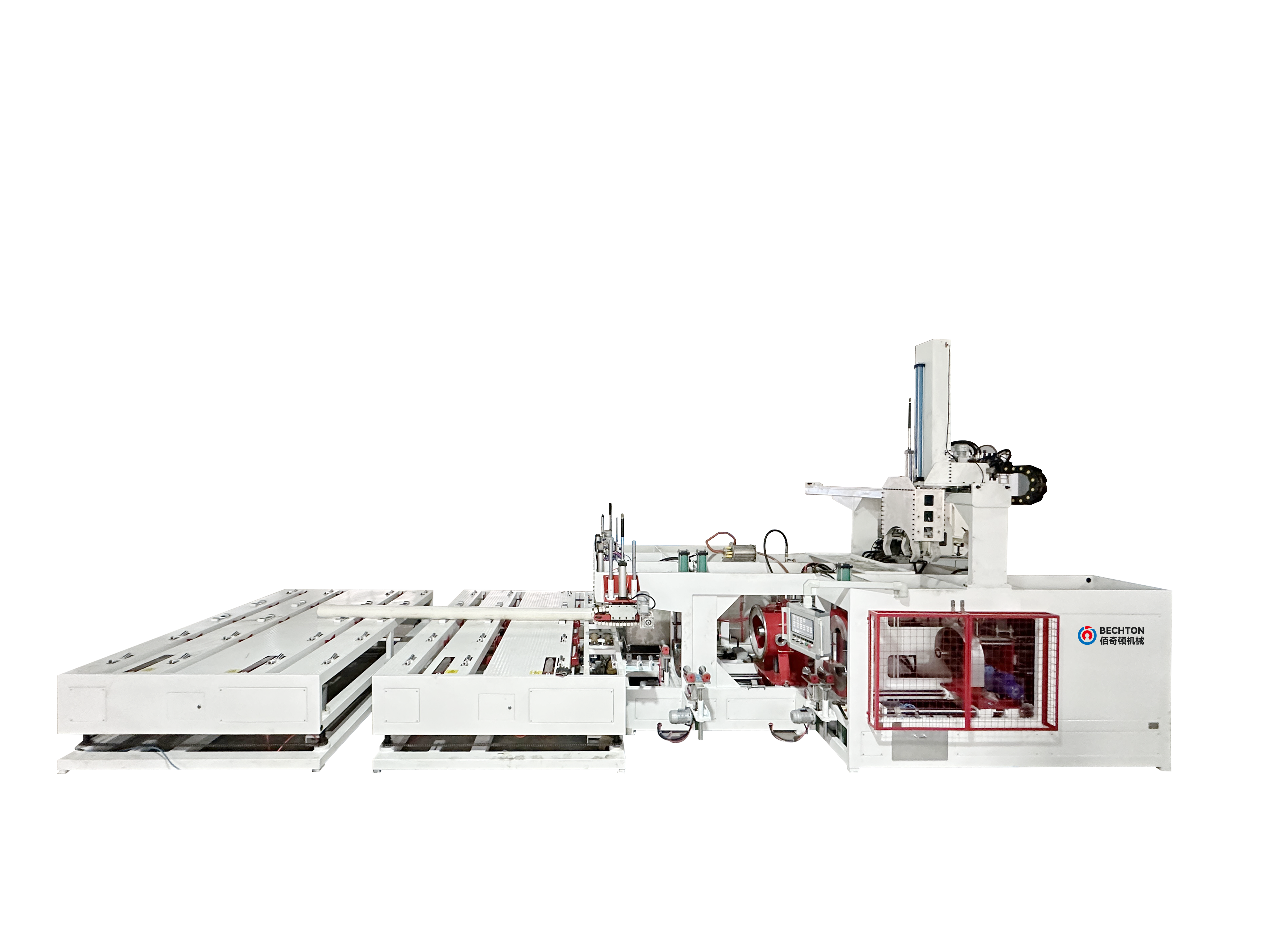

How Energy-Efficient Design Lowers Operating Costs in PVC-O Pipe Extrusion Line

Understanding Specific Energy Consumption (Wh/kg) in Extrusion Processes

PVC-O pipe extrusion lines today typically use around 100 Wh per kilogram, according to Rollepaal's research from 2025. Most of this energy goes toward drive systems at about 65%, while heating takes another 10% and things like cooling systems account for roughly 25%. These numbers really matter when it comes to how much companies spend on production because better energy efficiency means less power needed to actually melt and form the PVC-O material. When manufacturers tweak the screw geometry and apply special coatings to barrels that cut down on friction, they can significantly reduce mechanical resistance. The result? Specific energy consumption drops by as much as 15% compared with older, traditional systems.

Advanced Plastic Extruder Design That Reduces Mechanical and Thermal Load

The latest extruder models now feature tapered screws along with segmented barrels, which helps cut down on shear stress when working with PVC-O materials. This design actually brings down those peak melt temps somewhere between 8 to 12 degrees Celsius. Lower temperatures mean less chance of thermal degradation happening, plus it saves quite a bit on heating energy overall. According to research published in 2025, these new configurations also slash motor torque needs by about 22 percent. The result? Components last longer before needing replacement, and there's definitely less money spent on regular maintenance checks too.

Barrel Insulation and Precision Temperature Control to Minimize Energy Waste

High-performance ceramic-fiber insulation wraps reduce heat loss by 40% compared to traditional mineral wool. When paired with PID-controlled heating zones, this setup prevents temperature overshoots—a major source of energy waste. Precision control also enables faster startups, saving 18—25 kWh per production cycle in preheating energy.

Optimizing Extrusion Temperatures Without Sacrificing PVC-O Pipe Quality

Modern extrusion equipment runs around 165 to 175 degrees Celsius when working with PVC-O material, which is actually about 10 degrees cooler than what was standard before. Despite this lower temperature range, manufacturers still manage to keep the pipe impact strength well over 30 kJ per square meter. The latest systems monitor viscosity as they go along, making adjustments to the barrel heat so the product stays consistent even with less overall heating. Industry reports show that these new methods cut down on energy usage somewhere between 20 and 30 percent, all while keeping those critical pressure ratings intact. Several independent testing labs have confirmed these results based on their assessments from earlier this year.

Variable-Speed Drives and Real-Time Energy Optimization in PVC-O Pipe Extrusion Line

Dynamic Motor Output Control Using Variable-Speed Drives (VSDs)

Variable speed drives, or VSDs for short, work by adjusting how much power goes to motors as needed during extrusion processes. This means they can cut down on wasted energy compared to older fixed speed systems that just run at full blast all the time. According to a study published by Parallel Extrusion last year, factories using VSD technology saw their energy bills drop by about a quarter without slowing down production. The way these drives operate is pretty clever actually. They can scale power usage anywhere from 30% up to 100%, depending on what kind of materials are being processed and how fast things need to move through the system. This flexibility helps protect equipment from unnecessary wear and tear while also cutting back on those annoying energy losses when machines sit idle but still draw power.

Case Study: Energy Savings in Modern Extrusion Lines

A major PVC-O pipe manufacturer achieved 18% annual energy savings through VSD optimization. PLC-controlled drives automatically adjusted screw speeds during high-pressure water pipe production, reducing peak load phases by 42 minutes per shift. Real-time monitoring revealed that every 10% decrease in motor load translated to an hourly savings of 6.7 kWh.

Fine-Tuning Extruder Speed and Motor Settings for Peak Efficiency

Getting the most out of extrusion processes means operators need to tweak those extruder speeds right around that sweet spot of optimal RPMs, usually within about 2% either way when working with today's control systems. The tighter control really cuts down on unnecessary power consumption whenever switching between different pipe sizes without compromising what comes out the other end. Most folks running plants will tell you this works best, based on what we've seen from surveys across the industry last year. When manufacturers combine tight temperature management in the barrels (keeping things stable within just one degree Celsius) along with variable speed drive settings, they typically save somewhere between 12 to 15 percent on energy bills for their thermal cycling needs during non-stop production runs.

Reducing Idle and Standby Energy Loss in PVC-O Pipe Extrusion Line Systems

PVC-O pipe extrusion lines typically waste 12—18% of total energy during non-operational periods, making idle/standby optimization essential. Modern energy management systems address this through two targeted strategies:

Smart Shutdown Protocols to Minimize Standby Energy Consumption

Intelligent sensors monitor line activity and automatically power down ancillary systems—such as hydraulic pumps and cooling fans—after 8—12 minutes of inactivity. This eliminates unnecessary standby consumption, reducing energy drain by 38—55% compared to conventional setups.

Automated Idling Controls for Lowering Off-Cycle Power Use

During brief pauses (<15 minutes) for material changes or inspections, variable-frequency drives reduce main motor speeds by 60—75% while maintaining operational barrel temperatures. This dual-mode operation preserves readiness while cutting idle energy use by 240—380 kWh per tonne of produced pipe, according to 2023 polymer processing benchmarks.

Total Productive Maintenance (TPM) as a Strategy to Sustain Energy Efficiency

Preventive Maintenance Routines That Reduce Energy Waste

Implementing Total Productive Maintenance or TPM has been shown to cut down on energy expenses for PVC-O extrusion lines somewhere around 12 to maybe even 18 percent according to Ponemon's research from last year. When maintenance staff regularly oil those gearboxes and keep the screw drives properly lubricated, they actually reduce all that wasted energy from friction. And don't forget about checking how motors are aligned because misalignment causes them to pull way too much current. Factory workers who go through proper training for their daily walkarounds tend to spot those tiny insulation gaps that might seem small but end up costing about 2 to 3 kilowatt hours worth of heat loss for every metric ton produced. Finding these issues early helps maintain good electrical performance across operations.

Impact of Worn Screws, Heaters, and Seals on Specific Energy Consumption

Degraded components directly increase energy use per kilogram of PVC-O pipe:

| Component | Energy Penalty (Wh/kg Increase) | Root Cause |

|---|---|---|

| Worn Screw | 8—12 | Inefficient material shear |

| Faulty Heaters | 5—9 | Overcompensation cycles |

| Leaking Seals | 3—6 | Compressed air waste |

Replacing these parts during planned TPM intervals eliminates cumulative energy waste, which accounts for up to 22% of total consumption in aging systems.

TPM’s Role in Long-Term Cost Reduction for PVC-O Pipe Manufacturing

A three-year TPM program at a leading manufacturer reduced energy-related operational costs by $740,000 annually. Cross-functional teams using standardized checklists achieved 85—90% first-time fix rates for energy-draining faults—significantly higher than the 50—60% success rate in reactive models. This approach cuts lifecycle energy expenses by 30% and extends machinery service intervals by 18—24 months.

Automation and ROI: Measuring Long-Term Cost Savings in Energy-Saving Extrusion Lines

Extrusion Line Automation and Verified Cost Reductions in Modern Plants

Switching to automated PVC-O pipe extrusion lines can cut down yearly production expenses anywhere from 18 to 25 percent when compared with traditional manual methods according to the latest data from the Polymer Processing Report for 2024. When manufacturers install these systems with their servo driven extruders and automatic thickness controls, they typically see about 2.3 percentage points reduction in material waste plus around 12 to maybe even 15 percent drop in energy consumption per meter produced. Looking at recent findings from manufacturing studies back in 2023, companies investing in full automation generally recoup their investment costs between 16 and 28 months thanks mainly to reduced labor needs and better overall productivity rates across operations.

IoT Sensors and Real-Time Energy Monitoring for Proactive Optimization

Embedded IoT sensors reduce energy waste by 10—30% by detecting inefficiencies such as suboptimal barrel temperatures or motor overloads. Real-time dashboards track specific energy consumption (SEC), enabling rapid intervention. One facility reported a 40% reduction in off-cycle power use after implementing predictive algorithms.

Closed-Loop Feedback Systems That Maintain Optimal Energy Performance

Closed-loop control systems autonomously adjust motor speeds and heater outputs to sustain energy efficiency within 2% of theoretical limits. Studies show these systems maintain 92% energy consistency during continuous 24/7 production, outperforming manual operations by 19—27%.

Comparative Analysis: Traditional vs. Energy-Saving PVC-O Extrusion Lines

| Metric | Traditional Line | Energy-Saving Line | Improvement |

|---|---|---|---|

| kWh per ton of pipe | 520—580 | 390—420 | 25% ˝ |

| Annual output capacity | 8,000—9,000 tons | 9,500—11,000 tons | 19% ˕ |

| Payback period | N/A (Baseline) | 22 months | — |

| Labor costs per ton | $38—42 | $24—28 | 34% ˝ |

Data sourced from 2024 Extrusion Line Efficiency Study

Energy-saving extrusion lines deliver $240—$310 per ton in total cost savings, with 78% of operators confirming ROI within 36 months. Real-world data from 42 PVC-O pipe plants shows each production line reduces carbon emissions by 1.2 tons annually compared to conventional setups.

Frequently Asked Questions (FAQ)

What is the typical energy consumption for modern PVC-O pipe extrusion lines?

Modern PVC-O pipe extrusion lines typically use around 100 Wh per kilogram.

How do variable-speed drives contribute to energy efficiency?

Variable-speed drives adjust the power to motors as needed, reducing wasted energy and protecting equipment from wear and tear.

What role does Total Productive Maintenance (TPM) play in energy efficiency?

TPM helps reduce energy expenses by maintaining equipment, which decreases friction-related energy waste and ensures motors are properly aligned.

What kind of cost savings can be expected from automated extrusion lines?

Automated extrusion lines can reduce yearly production expenses by 18 to 25 percent, with ROI usually achieved within 16 to 28 months.

Table of Contents

- How Energy-Efficient Design Lowers Operating Costs in PVC-O Pipe Extrusion Line

- Variable-Speed Drives and Real-Time Energy Optimization in PVC-O Pipe Extrusion Line

- Reducing Idle and Standby Energy Loss in PVC-O Pipe Extrusion Line Systems

- Total Productive Maintenance (TPM) as a Strategy to Sustain Energy Efficiency

- Automation and ROI: Measuring Long-Term Cost Savings in Energy-Saving Extrusion Lines

- Extrusion Line Automation and Verified Cost Reductions in Modern Plants

- IoT Sensors and Real-Time Energy Monitoring for Proactive Optimization

- Closed-Loop Feedback Systems That Maintain Optimal Energy Performance

- Comparative Analysis: Traditional vs. Energy-Saving PVC-O Extrusion Lines

- Frequently Asked Questions (FAQ)