How PVC-O Pipe Extrusion Line Technology Enables Water-Saving Infrastructure

Biaxial Orientation Process: Thinner Walls, Higher Strength, Less Material

PVC-O pipes, also known as Biaxially Oriented Polyvinyl Chloride, are made using special extrusion lines that change regular PVC through a process called molecular realignment. Basically, the polymer gets stretched in two directions at once during manufacturing - around the circumference and along the length of the pipe. This double stretching creates pipes with walls about half as thick as traditional PVC-U, yet they actually have 30% better tensile strength and twice the impact resistance. What's really interesting is that this manufacturing technique cuts down on raw materials needed by anywhere from 25% to 40%, all while keeping the same level of structural integrity. And when it comes to leaks, PVC-O joints stay sealed at an impressive 99.7% rate even when pressure changes happen. Municipal water departments that switched to PVC-O systems saw their leakage problems drop by 18% each year compared to older ductile iron systems, as noted in the latest 2024 Water Infrastructure Report.

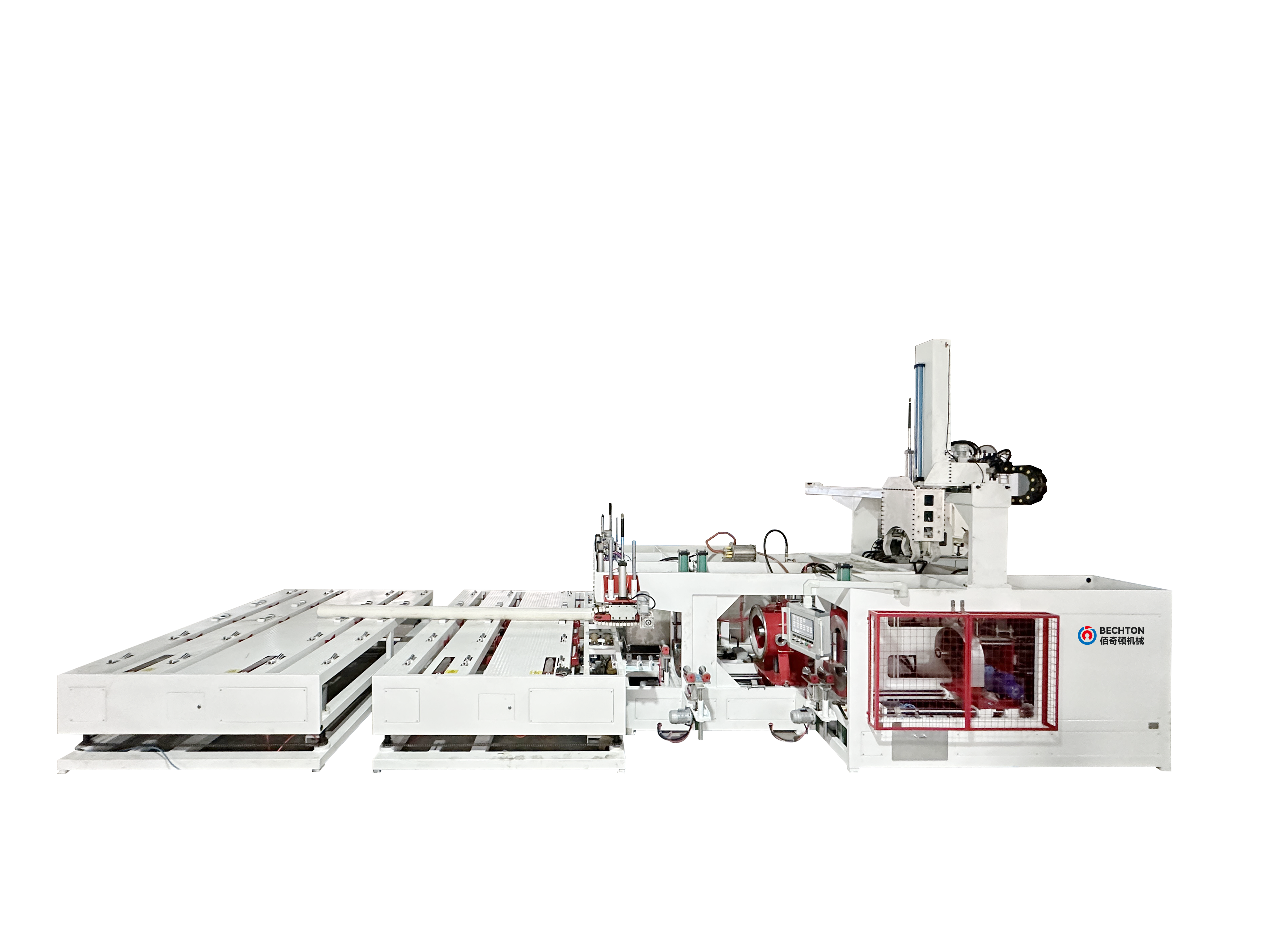

Key Extrusion Line Components Optimized for PVC-O Precision and Consistency

High-performance PVC-O extrusion lines integrate tightly coordinated subsystems to preserve molecular alignment and dimensional accuracy:

- Co-extrusion dies with ±0.05mm tolerance ensure uniform wall thickness across diameters (˜110â630mm)

- Temperature-controlled calibration units, stabilized to ±0.5°C, lock orientation before cooling

-

Digital servo-stretch modules apply synchronized radial and axial forces within tight force tolerances

Automated optical gauging continuously monitors ovality and diameter, feeding real-time corrections to prevent stress concentrations that trigger premature failure. Energy recovery systems integrated into advanced lines reduce power consumption by 20â30% during continuous operation. The result is consistent production of PN16âPN25 pressure-rated pipes capable of withstanding water hammer events exceeding 150 psiâsignificantly lowering infrastructure failure rates in aging networks.

Performance Advantages of PVC-O Pipes in Municipal Water Systems

PVC-O pipes really stand out in city water systems because of how they're built at the molecular level, not just what they're made of. When manufacturers orient the molecules in two directions during production, these pipes can have walls that are about 25% thinner than regular PVC-U but still handle pressures up to PN25. That gives them an amazing strength to weight ratio that engineers love seeing. The impact resistance? Well, it's roughly double what we get from standard PVC materials, and actually five times better than old school ductile iron pipes. This makes a big difference in areas where there's heavy traffic or earthquake risks, since broken pipes are a nightmare for everyone involved. Another major plus is that unlike metal pipes, PVC-O doesn't corrode electrochemically. This eliminates one of the main reasons pipelines fail over time, which means these pipes can last well over 50 years with hardly any maintenance needed. The inside surface is super smooth too, cutting down on water friction by around 30% compared to ductile iron. Less friction means pumps don't have to work as hard, so energy bills go down and the whole system has a smaller carbon footprint. Real world tests after earthquakes show these pipes keep working without issues, and maintenance costs stay about 40% lower throughout their lifespan thanks to their ability to resist chemicals, ground shifts, and wear and tear. Plus, since they're so light, installation crews can put them in place much faster – up to 35% quicker in some cases – which saves money on labor, reduces equipment rental time, and most importantly cuts down on the number of joints needed. Every joint removed is another potential leak spot eliminated from the system.

Sustainability Impact: Lifecycle Efficiency of PVC-O Pipe Extrusion Line Outputs

Reduced Embodied Energy andPVC-U and Ductile Iron Pipes

PVC-O pipes made using precision extrusion technology bring real sustainability benefits across their entire lifespan. The molecular orientation process actually reduces the amount of raw materials needed by around 30% compared to standard PVC-U pipes. And when it comes to energy consumption during production, these pipes have about 40% less embodied energy than traditional ductile iron options. This translates into roughly 35 to 50% fewer carbon dioxide emissions for every meter produced. The installation side also offers significant improvements. Because they're so much lighter, transportation requires 25% less fuel. Plus, there's less need for heavy trenching equipment. And since joints can be assembled faster, construction sites spend less time exposed to weather conditions that might otherwise increase emissions. Considering water systems contribute 2.1% to worldwide carbon emissions according to World Resources Institute research from last year, switching to PVC-O makes sense for fighting climate change without compromising on important factors like water flow capacity, pressure resistance, or how long the pipes will last.

Selecting and Implementing a Reliable PVC-O Pipe Extrusion Line

Critical Technical Specifications and After-Sales Support Considerations

When choosing equipment for PVC-O extrusion, technical details matter far more than just how fast things get done. Look for machines that maintain tight temperature control around ±0.5°C and handle consistent stretching throughout the entire diameter range from about 110mm all the way up to 630mm across different pressure ratings like PN5 through PN25. If the material isn't oriented properly or if there's variation in wall thickness, this can really hurt pressure performance sometimes cutting it down by nearly half. Make sure everything works together seamlessly – check that co-extrusion dies, calibration settings, and those servo stretch modules are actually working as part of one big system instead of just individual parts bolted together. Speaking of which, energy consumption becomes pretty important when running these operations at full capacity. The best setups typically save between 25% and 30% on electricity costs thanks to features like servo driven haul offs and systems that recover energy during braking processes.

After-sales support is equally decisiveâ78% of manufacturers cite responsive technical assistance as the top procurement factor (Global Pipe Equipment Survey, 2023). Confirm suppliers provide:

- Comprehensive operator training, including hands-on orientation parameter optimization for varying resin grades and pipe specs

- Dedicated spare-parts networks, with â±72-hour emergency dispatch guaranteed for critical stretch modules and calibration sleeves

- Preventive maintenance protocols, backed by remote diagnostics and uptime SLAs targeting >95% operational availability

Neglecting these elements risks production halts costing over $18,000/hour in high-volume operations. Partnering with a technically equipped provider ensures consistent, standards-compliant outputâdirectly supporting reliable, water-saving infrastructure delivery.

FAQ Section

What are PVC-O pipes and how are they different from PVC-U pipes?

PVC-O pipes are Biaxially Oriented Polyvinyl Chloride pipes, which are manufactured using a process that stretches the polymer in two directions, resulting in thinner walls and higher strength compared to traditional PVC-U pipes.

Why are PVC-O pipes considered sustainable?

Due to their manufacturing process, PVC-O pipes require less raw materials and have lower energy consumption, resulting in reduced carbon dioxide emissions. Additionally, their lighter weight reduces fuel requirements during transport, contributing to sustainability.

How do PVC-O pipes help in reducing leakage in water systems?

PVC-O pipes have joints that remain sealed at a high rate, drastically reducing leakage in municipal water systems compared to older materials like ductile iron.

What should be considered when selecting PVC-O pipe extrusion equipment?

Important considerations include tight temperature and stretching control, integrated system components, and responsive technical support to maintain consistent production and avoid costly halts.