How Biaxial Orientation Defines PVC-O Performance in Modern PVC-O Pipe Extrusion Line Systems

Molecular Alignment Mechanics: From Amorphous PVC to High-Strength, Crack-Resistant PVC-O

When biaxially oriented, amorphous PVC undergoes significant changes at the molecular level during extrusion. The process involves controlled radial expansion around 110 to 130 degrees Celsius combined with stretching along the length that organizes those long polymer molecules into distinct crystalline layers. What this means practically is stronger reinforcement all around the circumference. Tests show these modified pipes can resist impacts about three to three and a half times better than regular PVC products. They also fight off cracks much more effectively, with resistance improvements exceeding 300 percent in many cases. Under repeated pressure cycles, the fatigue life of these materials stretches somewhere between five and seven times longer than conventional alternatives. This makes PVC-O pipes capable of handling operating pressures roughly 25 to 35 percent higher than standard versions, yet they require approximately 15 to maybe even 20 percent less raw material to manufacture.

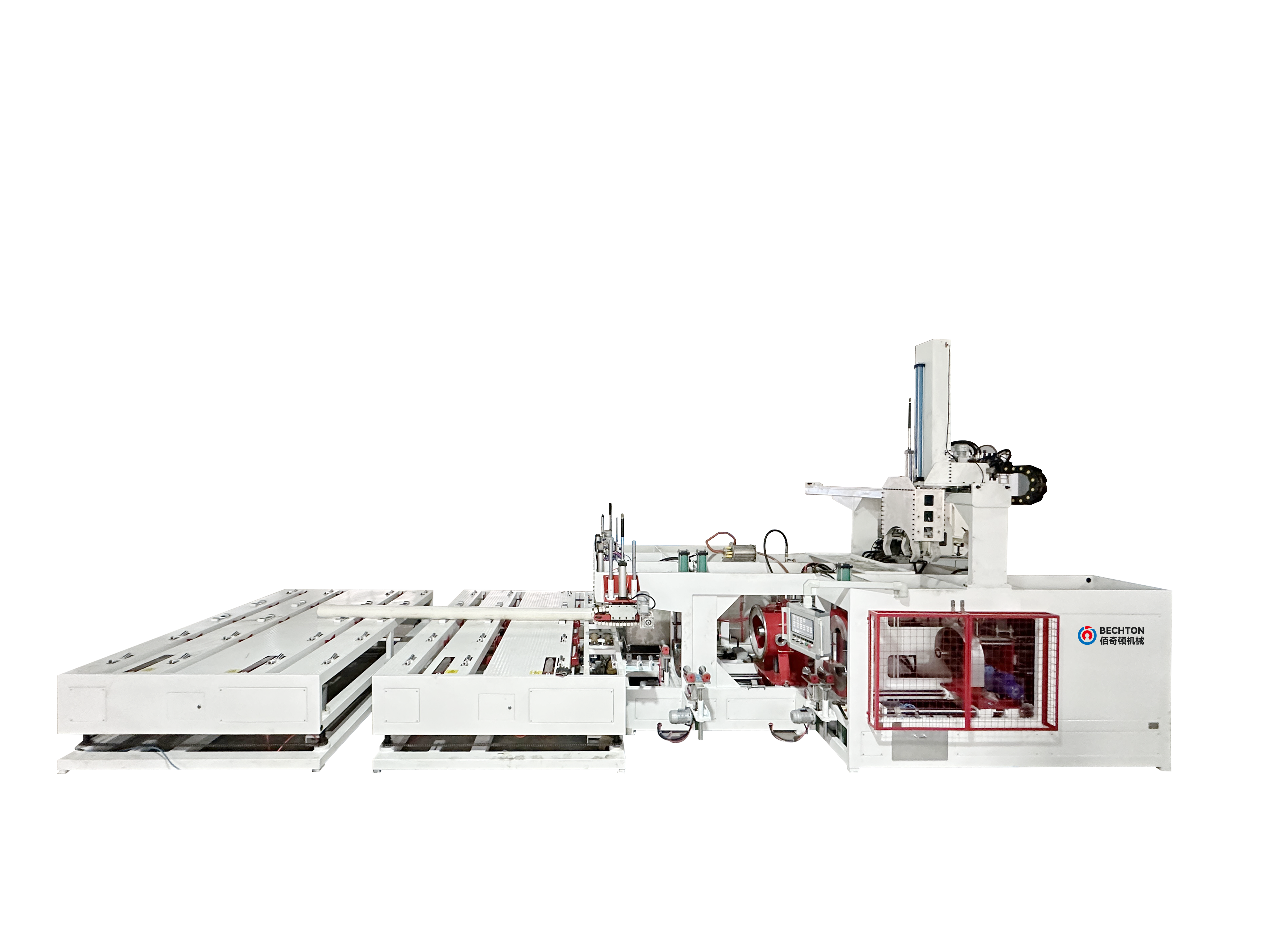

Twin-Screw Extrusion, Vacuum Calibration, and Post-Extrusion Stretching: Critical Stages in the PVC-O Pipe Extrusion Line Process

PVCO pipe extrusion lines today manage to get that precise biaxial orientation through three main steps working together seamlessly. First off, twin screw extruders mix up those PVC compounds really well, keeping temperatures stable within just one degree Celsius difference. After that comes the vacuum calibration stage. The pipes go through these tanks under negative pressure, which helps them maintain their size specifications down to about 0.3 millimeters accuracy. What happens next is pretty interesting. Post extrusion stretching units apply both radial and axial forces at the same time. Manufacturers usually do this with expanding mandrels combined with carefully adjusted haul off systems. This whole process aligns molecules uniformly throughout the material. And here's something manufacturers love hearing: AC frequency controlled drives during this final phase cut down on power usage by around 25 percent without messing up the orientation quality along the entire pipe length.

Intelligent Automation in the PVC-O Pipe Extrusion Line: Sensors, AI, and Real-Time Adaptive Control

Edge-Enabled Monitoring and Closed-Loop PLC Feedback for Dimensional Stability and Wall Uniformity

Edge sensors spread across production lines track melt pressure variations around half a bar, temperatures fluctuating within one degree Celsius, plus haul-off tension continuously. These readings get sent straight to PLC controllers which tweak die gaps, adjust screw speeds, and modify cooling rates almost instantly. The whole system works together to keep wall thickness variations below 0.15 mm, something really important when we need consistent biaxial orientation properties. When infrared cameras spot cooling problems early on, they trigger automatic recalibration processes before any serious crystallinity issues develop. According to industry standards, these kinds of monitoring systems cut down on dimensional rejects by about 40 percent, making them pretty reliable for products that must meet specific pressure requirements.

AI-Optimized Thermal Profiling and Predictive Maintenance for Extruder Wear and Die Swell Compensation

Modern neural network systems look at past extrusion records together with real time sensor information so they can tweak the temperature settings in different parts of the barrel and adjust how fast the screw turns. This helps compensate when there are changes in how much the material swells as it goes through the die, which happens because different batches of resin behave differently. At the same time, special vibration sensors send data to machine learning programs that actually spot potential bearing problems well before they happen, sometimes predicting failure over three days ahead. That cuts down on unexpected stoppages by about two thirds according to recent tests. The AI also makes automatic adjustments to pressure settings as screws start to wear out, keeping product dimensions within spec even as tools degrade over time. All these optimizations together cut energy costs around 22 percent and add roughly 300 extra hours between necessary maintenance stops, making production runs both cleaner and longer lasting.

Energy-Efficient Design of the PVC-O Pipe Extrusion Line: Regenerative Drives and Smart Thermal Management

Regenerative drive systems work by capturing kinetic energy when machines slow down, turning that energy back into electricity that can be used again. This process typically reduces overall motor power needs by around 20 to 30 percent. When it comes to thermal management, closed loop systems are grabbing about 60 to 70 percent of waste heat generated during barrel operations. Instead of letting this heat go to waste, the system redirects it for practical purposes like preheating raw materials or warming up parts of the factory itself. Compared to older systems, this approach cuts down on fresh energy requirements by approximately 28 percent for each production run. Another advancement worth mentioning is advanced induction heating technology which speeds up heat transfer rates by roughly 35 percent compared to traditional resistive methods. What's more, these systems maintain temperature stability within half a degree Celsius, helping prevent those dangerous thermal gradients that can damage materials during processing. All told, these improvements bring specific energy consumption down to between 180 and 220 watt hours per kilogram. That puts manufacturers about 15 percent under standard extrusion industry benchmarks and gives them a head start as countries continue to implement stricter efficiency standards worldwide.

Integrated Digital Manufacturing: Digital Twin Deployment and End-to-End Traceability in PVC-O Pipe Extrusion Line Operations

From Real-Time Sensor Fusion to Virtual Commissioning and Lifecycle Analytics

Digital twin technology creates virtual copies of actual production systems using real time data from IoT sensors. These digital models keep track of things like melt pressure, temperature changes, and how stable dimensions stay throughout manufacturing. What makes this approach so powerful is that it allows for quality predictions when viscosity starts changing, lets companies test new product formulas virtually before making physical samples, and spots problems with crystal structures that might indicate material issues at the molecular level. Manufacturers can simulate how heat affects materials over time and where stresses build up, which helps them adjust stretching processes without waiting for trial and error. This results in thinner walls varying less than 18% across products while keeping them resistant to cracking. If measurements drift beyond 0.3 mm tolerance, the system automatically adjusts extrusion speeds on its own. With blockchain tracking, every step gets recorded from initial raw materials all the way through to finished pipes. Quality documents generated this way cannot be altered and are easy to access through QR codes. Having complete visibility from start to finish reduces waste by around 22%, and also helps predict how long infrastructure will last when subjected to different pressure levels over time.

Frequently Asked Questions

What is the benefit of biaxial orientation in PVC-O pipes?

Biaxial orientation significantly enhances the mechanical properties of PVC-O pipes, making them more resistant to impacts, cracks, and fatigue. This process allows the pipes to handle higher operational pressures while reducing material usage during manufacturing.

How does intelligent automation improve the extrusion process?

Intelligent automation uses sensors and AI to continuously monitor and adjust parameters like temperature, pressure, and tension during extrusion. This ensures consistent wall thickness and dimensional accuracy, reducing waste and improving product quality.

What are regenerative drives and how do they enhance energy efficiency in PVC-O extrusion?

Regenerative drives capture kinetic energy during machine slowdown and convert it back into usable electricity, reducing the overall motor power demand. This enhances energy efficiency, reduces operational costs and minimizes environmental impact.

How does digital twin technology contribute to the extrusion process?

Digital twin technology uses real-time data to create virtual models of production systems. This enables predictive analysis, quality assurance, and the testing of new product formulas without physical sampling, optimizing the entire manufacturing process.

Table of Contents

- How Biaxial Orientation Defines PVC-O Performance in Modern PVC-O Pipe Extrusion Line Systems

- Intelligent Automation in the PVC-O Pipe Extrusion Line: Sensors, AI, and Real-Time Adaptive Control

- Energy-Efficient Design of the PVC-O Pipe Extrusion Line: Regenerative Drives and Smart Thermal Management

- Integrated Digital Manufacturing: Digital Twin Deployment and End-to-End Traceability in PVC-O Pipe Extrusion Line Operations

- Frequently Asked Questions