Teknologi Utama dan Automasi dalam Garisan Pengeluaran Paip PVC-O

Sistem Kawalan Maju untuk Ketepatan dalam Pengeluaran PVC-O

Garis pengeluaran paip PVC-O hari ini bergantung pada sistem PLC untuk mengekalkan rongga dimensi dalam lingkungan 0.15mm sepanjang setiap kitaran pengeluaran. Sistem kawalan lanjutan ini mengendalikan pelbagai zon suhu sambil membuat penyesuaian terhadap perubahan tekanan, membolehkan operator mengubah aliran lelehan mengikut keperluan semasa pemprosesan. Satu kajian terkini dari bidang pemprosesan polimer menunjukkan peningkatan ini mengurangkan ketidaktepatan ketebalan dinding hampir sebanyak 40% berbanding teknik ekstrusi yang lebih lama. Tahap ketepatan ini memberi kesan besar terhadap kekuatan paip akhir menentang letupan di bawah tekanan.

Pengintegrasian Automasi dan Pemantauan Secara Masa Nyata

Pemakan bahan yang berfungsi secara automatik bekerjasama dengan sensor pintar yang disambungkan kepada internet of things, memantau perkara seperti jumlah daya yang dikenakan oleh skru dan ketebalan bahan lebur setiap kira-kira 50 milisaat. Dengan sistem automatik sebegini beroperasi di latar belakang, pasukan penyelenggaraan boleh mengesan apabila komponen dalam mesin mula haus jauh sebelum sebarang kerosakan berlaku. Sesetengah kilang memberitahu kami bahawa mesin mereka kekal beroperasi selama kira-kira 92% daripada masa, iaitu jauh lebih baik daripada keputusan sebelum ini apabila pekerja perlu memeriksa semua perkara secara manual. Perbezaannya adalah sekitar 28 peratus menurut data yang dikumpulkan oleh syarikat besar yang menghasilkan produk plastik melalui proses ekstrusi.

Sistem Ekstrusi Skru Kembar dan Kehomogenan Leburan

Konfigurasi skru kembar berputar berlawanan mencapai kehomogenan lelehan sebanyak 99.8% dengan mengenakan daya ricih terkawal ke atas sebatian PVC. Reka bentuk saling masuk ini menghapuskan kantung bahan yang tidak bercampur yang secara tradisinya menyebabkan kepekatan tegasan, meningkatkan rintangan impak paip sebanyak 40% berbanding pengeluar skru tunggal. Geometri skru lanjutan mengoptimumkan taburan masa tinggal, meminimumkan risiko degradasi haba semasa pemprosesan kelajuan tinggi.

Pemprosesan PVC-O Secara Dalam Talian: Pengoptimuman Berasaskan Data berbanding Kaedah Kelompok

Sistem orientasi selanjar dalam talian menyesuaikan nisbah regangan secara dinamik menggunakan data ketebalan dinding paip masa sebenar, membolehkan pengeluaran paip DN630 dalam satu laluan dengan had diameter 15% lebih ketat berbanding kaedah kelompok berperingkat. Algoritma pembelajaran mesin menganalisis lebih daripada 120 parameter proses setiap minit, mengurangkan penggunaan tenaga sebanyak 22% sambil mengekalkan pematuhan dengan piawaian ISO 16422.

Orientasi Molekul dan Prestasi Mekanikal Paip PVC-O

Asas Proses Orientasi Aksial dan Biaxial

Apa yang menjadikan paip PVC-O begitu kuat? Jawapannya terletak pada cara kita menyusun molekul-molekul tersebut semasa proses pengeluaran. Apabila membuat paip ini, pengilang menggunakan teknik regangan khas sama ada sepanjang panjang paip (orientasi aksial) dan juga merentasinya (orientasi biaxial). Proses regangan ini menyusun semua rantaian polimer kecil tersebut dalam arah tertentu. Bagi paip biasa, penyusunan sebegini tidak dilakukan langsung. Tetapi dengan PVC-O, hasilnya adalah sesuatu yang luar biasa. Ujian menunjukkan bahawa apabila kaedah biaxial ini digunakan, kekuatan yang dihasilkan di sekeliling lilitan paip meningkat kira-kira dua kali ganda berbanding keupayaan paip PVC piawai. Ini bermakna jurutera tidak perlu membina paip berdinding tebal untuk menghadapi situasi tekanan tinggi, yang seterusnya menjimatkan kos dan ruang dalam pemasangan bawah tanah di mana setiap inci sangat penting.

Bagaimana Penyusunan Molekul Meningkatkan Sifat Mekanikal

Penstrukturan semula struktur molekul amorf PVC-U kepada matriks berlapis dan terarah meningkatkan secara ketara sifat mekanikal utama:

- Kekuatan Tarik : 90 MPa (berbanding 50 MPa untuk PVC-U)

- Ketahanan impak : Sehingga tiga kali ganda lebih tinggi daripada PVC konvensional

- Daya Tahan Lelah : Peningkatan sebanyak 2.5 kali ganda di bawah beban kitaran (Battenfeld-Cincinnati 2023)

Penyelarasan ini meminimumkan kepekatan tegasan dan menghalang perambatan retakan, walaupun pada ketebalan dinding yang dikurangkan.

Perbandingan Prestasi: Paip PVC Berorientasi vs. Paip PVC Tidak Berorientasi

Paip PVC-O boleh mencapai tahap tekanan yang sama seperti pilihan PVC biasa atau logam sambil menggunakan 34 hingga 50 peratus kurang bahan secara keseluruhan. Sebagai contoh, paip DN150 mempunyai berat kira-kira 18.7 kilogram per meter berbanding sekitar 28.9 kg/m untuk versi PVC-U piawai menurut kajian Ponemon dari tahun 2022. Perbezaan ini sebenarnya mengurangkan kos pemasangan sebanyak kira-kira 22%. Dan apabila tiba pada prestasi dalam cuaca sejuk, PVC bukan terarah cenderung gagal lebih kerap semasa kitaran beku-cair. Ujian menunjukkan ia gagal kira-kira 60% lebih kerap berbanding alternatif terarah, yang menjadikannya agak tidak boleh diharapkan di kawasan dengan suhu yang kerap berubah.

Pengkelasan Bahan Berdasarkan Integriti Struktur dan Ketahanan

Piawaian seperti ISO 16422 mengkelaskan paip PVC-O kepada Kelas T1–T4 berdasarkan kekuatan hidrostatik (25–50 bar) dan nilai kekuatan minimum yang diperlukan (MRS). Paip Kelas T4, direkabentuk untuk keadaan tanah agresif, menunjukkan jangka hayat perkhidmatan melebihi 40 tahun dengan pemanjangan â 1% di bawah beban berterusan.

Meningkatkan Kualiti Produk Melalui Inovasi Teknologi

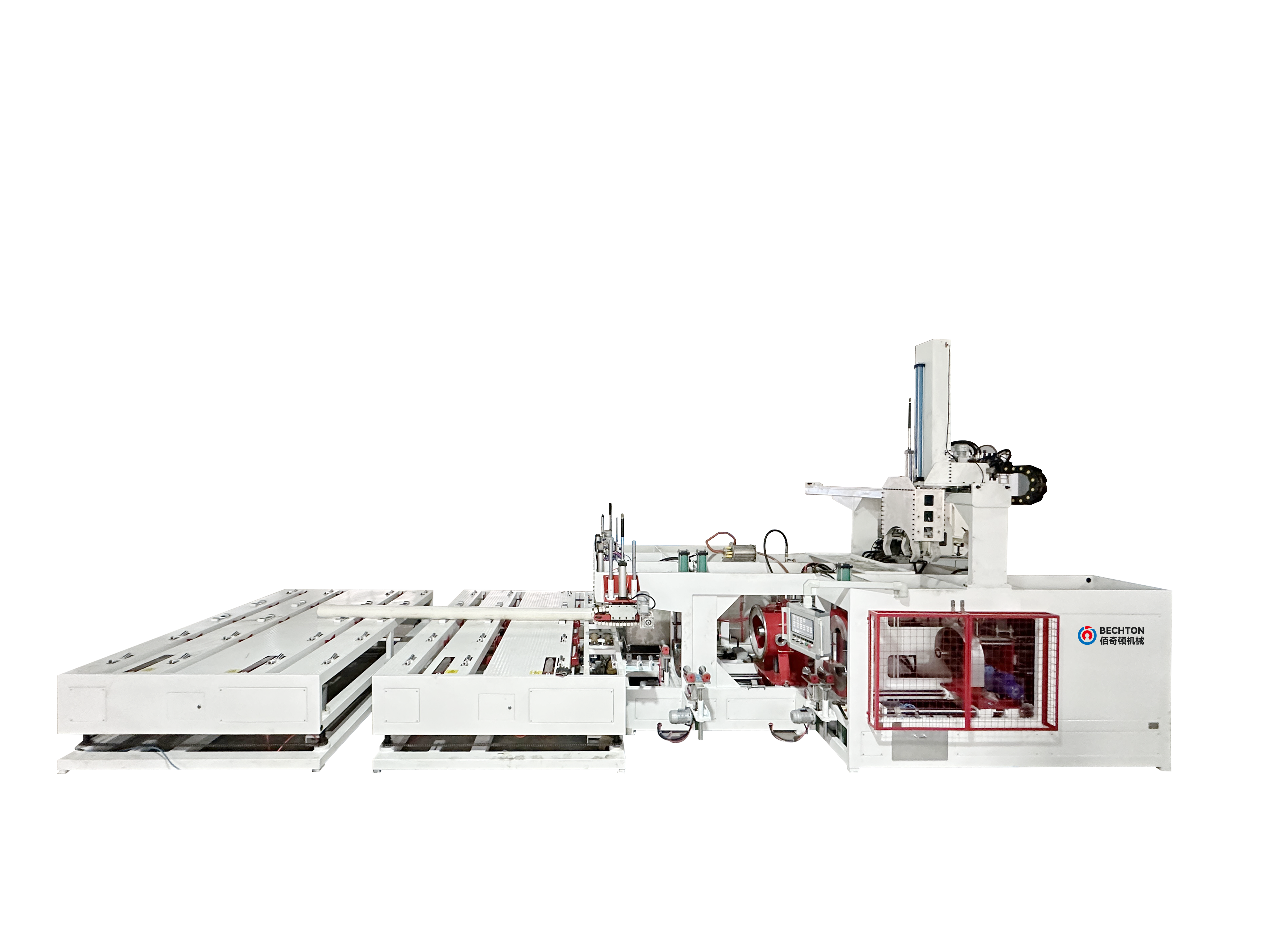

Talian pengeluaran paip PVCO moden kini melaksanakan teknologi canggih yang meningkatkan kualiti produk melampaui had pengeluaran tradisional. Inovasi ini memastikan prestasi struktur yang konsisten tanpa mengorbankan kelajuan pengeluaran, mengubah pembuatan PVC-O kepada disiplin berasaskan ketepatan selaras dengan tuntutan infrastruktur moden.

Inovasi Meningkatkan Kekuatan Struktur dan Kemasan Permukaan

Peralatan ekstrusi tahap mikron memastikan taburan bahan yang seragam, menghapuskan kawasan lemah pada dinding paip. Sistem acuan yang dikawal suhu dengan ketepatan ±0.5°C meningkatkan penyelarian molekul yang optimum semasa orientasi, menambah rintangan tekanan letupan sebanyak 30–40% berbanding sistem lama. Pemantauan viskositi polimer secara masa nyata menyesuaikan tetapan ekstrusi secara dinamik, mencegah kecacatan permukaan yang biasa berlaku dalam teknik pengeluaran terdahulu.

Mencapai Ketepatan Dimensi dan Ketahanan Jangka Panjang

Sistem pengukuran laser yang automatik boleh melakukan lebih daripada 200 imbasan perenggan setiap minit sambil memastikan mandrel tetap diletakkan dengan betul dalam jarak kira-kira 50 mikron. Proses penyejukan melibatkan beberapa peringkat di mana perisian pengurusan haba pintar membantu menghilangkan tekanan sisa yang menjengkelkan. Menurut piawaian industri (ISO 9080), ini harus memberikan jangka hayat peralatan melebihi 100 tahun apabila dikekalkan dengan betul. Ujian dunia sebenar dalam pelbagai keadaan telah menunjukkan sesuatu yang cukup mengagumkan juga sistem canggih ini mengurangkan variasi diameter kira-kira tiga perempat berbanding kaedah tradisional.

Meminimumkan Kecacatan Dengan Teknologi Mesin Lanjutan untuk Paip PVC-O

Kamera berkelajuan tinggi dalam talian yang bekerja bersama dengan sistem penglihatan mesin dapat melihat retakan mikro kecil yang hanya berukuran 0.2mm ketika berjalan pada kelajuan lebih 25 meter sesaat. Apabila sistem mengesan pencemaran, ia mencetuskan mekanisme pembersihan automatik yang menembak dalam masa kira-kira setengah saat, yang benar-benar membantu mengurangkan bahan yang sia-sia. Menurut beberapa penyelidikan baru-baru ini yang diterbitkan pada tahun 2023 mengenai pemprosesan polimer, sistem bersepadu jenis ini berjaya mengekalkan kadar ralat di bawah 0.02%. Ini agak mengagumkan jika dibandingkan dengan kaedah kawalan kualiti lama, mengalahkan mereka sebanyak 15 kali lebih berkesan. Kebanyakan kaedah tradisional tidak dapat menyamai tahap ketepatan dan kelajuan ini dalam persekitaran pembuatan moden.

Kemajuan ini meletakkan pembuatan PVC-O sebagai penanda aras dalam jaminan kualiti, menyokong projek infrastruktur air dengan keperluan ketahanan dan kemampanan yang ketat.

Memaksimumkan kecekapan operasi dalam pengeluaran PVC-O

Penyelesaian Siap Pakai untuk Uptimes dan Throughput yang Tinggi

Garis pengeluaran PVC-O hari ini dilengkapi dengan sistem sepenuhnya automatik yang direka untuk meningkatkan pengeluaran sambil mengurangkan hentian mesin. Sistem-sistem ini biasanya termasuk skru tork tinggi yang berfungsi bersama kawalan suhu PLC bagi membantu mengekalkan pemprosesan bahan yang konsisten. Untuk paip diameter besar, susunan sedemikian mampu menghasilkan lebih daripada 1.2 tan sejam. Apa yang menjadikan mereka benar-benar menonjol ialah kelajuan tindak balas mereka – pelarasan masa sebenar berlaku dalam tempoh kira-kira setengah saat, yang mengurangkan pembaziran bahan antara 18 hingga 22 peratus berbanding kaedah manual lama. Kebanyakan kilang kini telah mengadopsi sistem kawalan terpusat, yang menghubungkan proses penyuapan di hujung hadapan dengan operasi penyejukan di hujung belakang. Integrasi sebegini mengekalkan kelancaran operasi mesin sebahagian besar masa, dengan sesetengah kemudahan melaporkan jangka hayat sehingga melebihi 95 peratus walaupun beroperasi secara berterusan siang malam, seperti yang dinyatakan dalam dapatan terkini Laporan Industri Beierextrusion.

Kecekapan Tenaga dan Penyelenggaraan Berasaskan Ramalan dalam Sistem Ekstrusi Moden

Garis ekstrusi lanjutan mengurangkan penggunaan tenaga sebanyak 30%melalui tiga inovasi utama:

- Sistem Pemulihan Haba menggunakan semula tenaga haba sisa dari tangki penyejukan

- Pemacu berfrekuensi-pemboleh ubah mengatur beban motor berdasarkan data ketebalan dinding masa nyata

- Penyelenggaraan Ramalan AI mengesan keausan skru 150 - € 200 jam sebelum kegagalan

Apabila disatukan dengan pemantauan IoT, teknologi ini mengurangkan kos penyelenggaraan tahunan dengan $74,000-$120,000 setiap garisan sambil memastikan konsistensi berkualiti ISO 9001.

Menyeimbangkan Pengeluaran Atas Talian berbanding Pengeluaran Pukal untuk Output Optimum

| Faktor | Pemprosesan Dalam Talian | Pengolahan batch |

|---|---|---|

| Penggunaan Tenaga (kWh/tan) | 580–620 | 720–780 |

| Kapasiti keluaran | 25–30% Lebih Tinggi | Terhad oleh peringkat penyejukan |

| Penggunaan Bahan | 96–98% | 89–92% |

Seperti yang ditunjukkan dalam kajian penggunaan bahan oleh Faygoplas (2024), pemprosesan dalam talian menghapuskan langkah-langkah pengendalian perantaraan, memendekkan masa kitar sebanyak 15–20% sambil mengekalkan had luar diameter yang ketat pada ±0.3mm. Kaedah ini telah menjadi piawaian bagi kemudahan yang menghasilkan lebih daripada 5,000 tan metrik setiap tahun.

Evolusi Industri dan Trend Masa Depan dalam Teknologi PVC-O

Perkembangan Sejarah dan Inovasi PVC-O Generasi Baharu

Kisah pengeluaran PVC-O benar-benar bermula pada tahun 70-an dengan kaedah pemprosesan secara kumpulan. Syarikat-syarikat menyukai pendekatan ini kerana ia tidak memerlukan pelaburan awal yang besar, walaupun dari segi kecekapan tenaga ia kurang cekap. Semuanya berubah sekitar tahun 2012 apabila pengilang mula menggunakan teknologi orientasi dalam talian. Menurut laporan daripada Kumpulan Petzetakis pada tahun 2019, sistem baru ini mengurangkan penggunaan tenaga sebanyak antara 18 hingga 22 peratus sambil membolehkan kilang beroperasi secara berterusan tanpa perlu berhenti dan mula semula. Barisan ekstrusi moden kini dilengkapi pelbagai sensor IoT yang memantau penyusunan molekul semasa pemprosesan, membolehkan ketepatan dimensi mencapai sehingga 0.03mm—kira-kira tiga kali lebih baik daripada peralatan lama. Sejak tahun 2015, kelajuan pengeluaran telah meningkat kira-kira 140%, dan terdapat dakwaan bahawa sistem akan datang mungkin mencapai kadar keluaran sebanyak 45 meter per minit berkat kepada pengoptimuman acuan secara dinamik oleh AI.

Pemacu Kelestarian dan Trend Penerimaan Pasaran

Peraturan alam sekitar yang semakin ketat di seluruh dunia sedang mendorong syarikat-syarikat beralih kepada bahan PVC-O lebih cepat daripada sebelum ini. Kajian yang menilai keseluruhan kitar hayat produk ini menunjukkan PVC-O menghasilkan sekitar 31% kurang karbon berbanding plastik PVC-U biasa. Menurut Laporan Pasaran Disahkan dari tahun lepas, kita sedang melihat pasaran yang berkembang hampir 10% setiap tahun sehingga 2033, kebanyakannya disebabkan keperluan bandar-bandar terhadap sistem paip air yang lebih baik. Kilang-kilang kini menggunakan teknologi penyejukan gelung tertutup yang menjimatkan sekitar 7,500 liter setiap jam mereka mengendalikan lini pengeluaran. Tambahan pula, terdapat formula baru yang dibangunkan untuk mengurangkan sisa hampir 20%. Perancang bandar juga telah mula meminta secara khusus PVC-O dalam sistem tekanan. Analis yang memantau bidang ini melaporkan bahawa komponen kini tahan lebih lama, dengan penggantian berlaku 27% kurang kerap sejak awal dekad ini. Ini membuktikan betapa boleh dipercayainya bahan ini apabila dipasang dengan betul.

Soalan Lazim

Apakah faedah utama menggunakan paip PVC-O?

Paip PVC-O menawarkan kekuatan tegangan yang lebih tinggi, rintangan terhadap hentaman dan kelesuan, serta penjimatan bahan yang ketara, menjadikannya berkesan dari segi kos dan tahan lama untuk situasi tekanan tinggi.

Mengapa pengorientasian molekul penting dalam pengeluaran paip PVC-O?

Pengorientasian molekul menyelaraskan rantaian polimer untuk meningkatkan sifat mekanikal seperti kekuatan dan rintangan, yang mengurangkan keperluan bahan dan meningkatkan prestasi paip secara keseluruhan.

Bagaimanakah automasi memperbaiki pengeluaran paip PVC-O?

Automasi membolehkan pemantauan dan kawalan masa nyata, mengurangkan pembaziran bahan, dan meningkatkan tempoh operasi mesin, membawa kepada pengeluaran yang cekap dan konsisten.

Apakah perbezaan antara pemprosesan dalam talian dan pemprosesan pukal dalam pengeluaran PVC-O?

Pemprosesan dalam talian menawarkan kecekapan tenaga, kelulusan, dan penggunaan bahan yang lebih tinggi berbanding pemprosesan pukal, menjadikannya lebih sesuai untuk pengeluaran skala besar.

Apakah faedah alam sekitar paip PVC-O?

Paip PVC-O mengurangkan jejak karbon sebanyak 31%, menawarkan ketahanan tinggi, dan memerlukan penggantian yang lebih sedikit, menyokong penyelesaian infrastruktur air yang lebih mampan.

Jadual Kandungan

- Teknologi Utama dan Automasi dalam Garisan Pengeluaran Paip PVC-O

- Orientasi Molekul dan Prestasi Mekanikal Paip PVC-O

- Meningkatkan Kualiti Produk Melalui Inovasi Teknologi

- Memaksimumkan kecekapan operasi dalam pengeluaran PVC-O

- Evolusi Industri dan Trend Masa Depan dalam Teknologi PVC-O

-

Soalan Lazim

- Apakah faedah utama menggunakan paip PVC-O?

- Mengapa pengorientasian molekul penting dalam pengeluaran paip PVC-O?

- Bagaimanakah automasi memperbaiki pengeluaran paip PVC-O?

- Apakah perbezaan antara pemprosesan dalam talian dan pemprosesan pukal dalam pengeluaran PVC-O?

- Apakah faedah alam sekitar paip PVC-O?