Energy and Material Efficiency in the PVC-O Pipe Extrusion Line

Reduced Energy Consumption via Optimized Biaxial Orientation

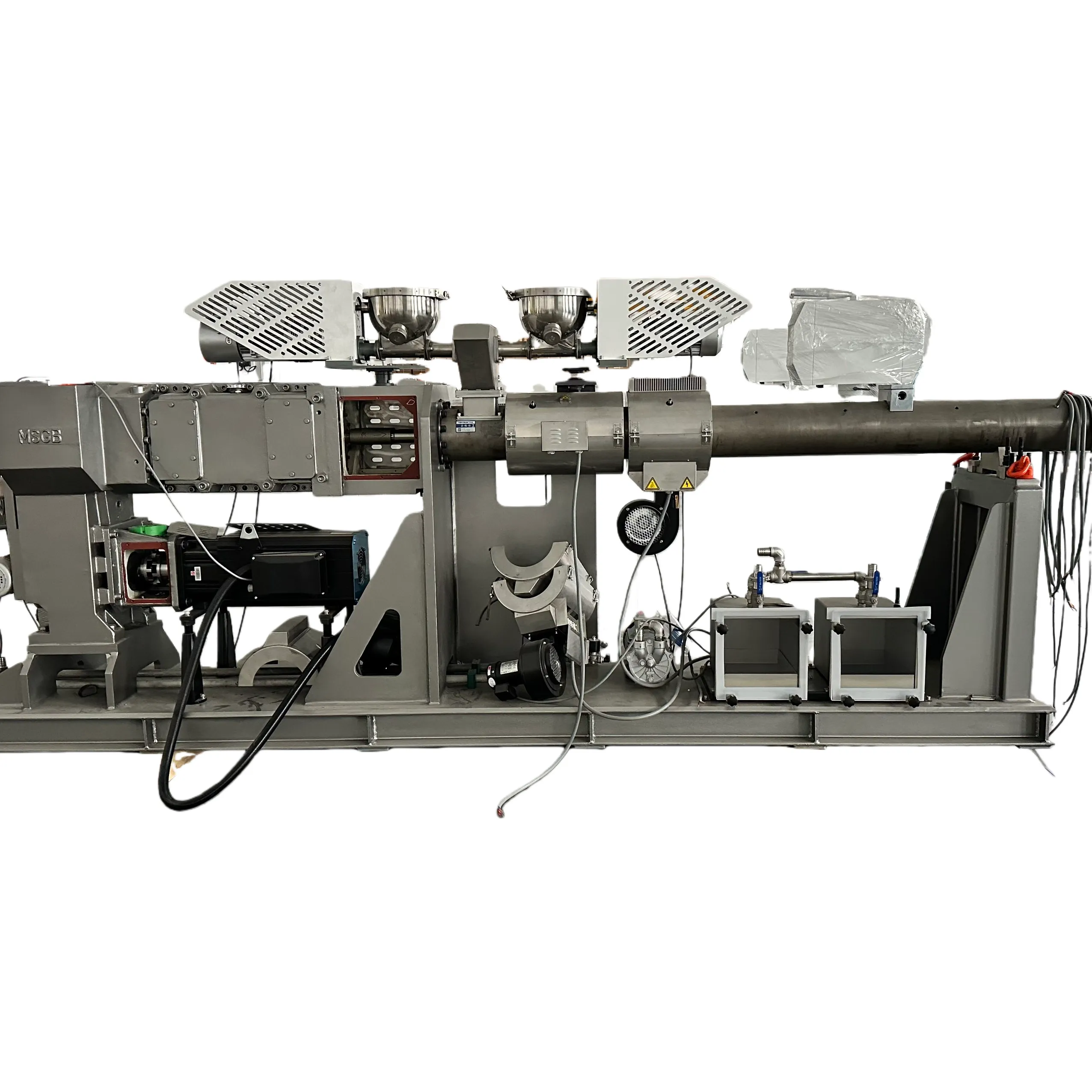

Today's PVCO (Polyvinyl Chloride Oriented) pipe extrusion systems have built-in biaxial orientation right from the start of production, which means no need for those extra energy hungry steps after manufacturing is done. By keeping materials flowing continuously through the system, these new lines cut down on heat loss problems and save around 15 to 25 percent in energy costs when compared with older PVC-U techniques. Smart control systems constantly tweak how much stretching happens both around and along the pipe as it forms, making sure molecules line up properly while wasting less power overall. Motor speeds can be adjusted on the fly too, so they only work as hard as needed when switching between different materials. All this makes production faster by about 30 percent, meaning less total energy spent per meter of pipe produced, all while still meeting strict size specifications within plus or minus 2 percent accuracy.

Thinner-Wall Design Enabled by Molecular Alignment—Less PVC, Same Strength

When we talk about biaxial orientation, what we're really looking at is a process that turns regular PVC into something much stronger and better performing. The technique involves aligning polymers both around the circumference and along the length of the material. What happens next? Well, this rearrangement at the molecular level actually boosts tensile strength by as much as double compared to normal PVC. Plus it makes the material more resistant to impacts. Manufacturers can then make their pipes thinner by anywhere from 30% to 50% while still keeping those important pressure ratings like PN16 and PN25 intact. And here's where things get interesting economically speaking. Less material means about 25% to 40% less raw materials needed per meter of pipe produced. That translates directly into lower resin costs and cheaper manufacturing all while maintaining good water flow properties and lasting quality over time. Another bonus comes from the lighter weight of these improved pipes. Transporting them requires roughly 18% to 22% less energy, which adds another layer of environmental benefit throughout the entire life cycle of the product.

Long-Term Environmental Performance of PVC-O Pipes in Infrastructure

Extended 50+ Year Service Life Minimizing Resource Turnover

PVC-O pipes have been shown to last well over 50 years when used in underground water systems. The extended lifespan means communities don't need to replace these pipes as often. Municipal water departments find they can go about 60% longer between replacements compared to older pipe materials. Recent testing from 2023 shows something pretty impressive too. When installed correctly, these pipes keep around 98% of their initial pressure strength even after sitting underground for half a century. This happens because they deform much slower than polyethylene options (about 70% slower creep rate) and naturally resist rust and chemicals breaking them down. Looking at actual field performance over 25 years, water companies consistently see maintenance expenses fall by roughly 40%. That translates into fewer resources pulled from the earth, less carbon released during repairs, and ultimately less debris ending up in landfills from old pipe removals.

Lower Embodied Energy vs. Ductile Iron and HDPE Alternatives

The benefits come down to two main things working together. First, when manufacturers align molecules during production, they can create walls that are much thinner while still maintaining strength. This means they need about 25% less PVC resin overall. Second, improvements in the extrusion process cut down on energy consumption during manufacturing by around 18% compared to old school PVC-U methods. Cities building new infrastructure with these PVC-O pipes are seeing some impressive results too. Studies show these projects have roughly 22% lower carbon footprint throughout their entire life cycle from installation all the way to eventual replacement. That kind of reduction really helps municipalities meet those tough climate targets for modernizing water systems without breaking the bank.

Third-Party Validation: LCA and EPD Compliance for PVC-O Pipe Extrusion Line

ISO 14040/44-Certified Cradle-to-Grave Life Cycle Assessment Results

Third party organizations have certified the environmental claims about our PVCO pipe extrusion line through proper ISO 14040/44 standards for Life Cycle Assessments. These comprehensive studies look at everything from where materials come from all the way through manufacturing, installation, regular maintenance work, and what happens when the pipes eventually get recycled at the end of their useful life. According to assessments done in 2023, there's been quite impressive improvements showing around 30 to 35 percent less contribution to global warming potential compared to traditional PVC production methods. Water usage drops by approximately 20% per meter of pipe produced as well. The assessments use recognized industry standard approaches like ReCiPe and TRACI to measure things such as how much energy goes into making these products, what kind of emissions result from production processes, and whether certain resources might be running low over time. With this kind of verified information forming the basis for Environmental Product Declarations (EPDs), city planners and others involved in infrastructure projects now have solid scientific evidence they can rely on when trying to comply with green building requirements set forth by various regulatory bodies across different regions.

Circular Economy Integration in PVC-O Pipe Extrusion Line Design

Design for Recycling: Compatibility with Post-Consumer PVC Streams

The PVCO pipe extrusion tech has been designed with circular thinking in mind. Advanced filters let manufacturers mix in around 30% post-consumer PVC regrind while still keeping the pipes strong enough for normal pressure demands. What does this mean? Less need for brand new polymer materials basically. For every ton of pipe made, we save about 24kg of fresh material going into production. The modular parts used in these extrusion machines can be taken apart and reused when upgrading equipment, recovering over 90% of materials in most cases. Standard sizes also make it easier to work with current recycling facilities for PVC products. And those solvent free joints? They keep the material clean through multiple reuse cycles too. This helps keep hundreds of tons out of landfills each year, which makes good business sense while also ticking all the boxes for true circular economy practices that many companies are now aiming for.

FAQ

What is the main advantage of biaxial orientation in PVC-O pipes?

Biaxial orientation aligns PVC molecules for increased strength, allowing thinner pipe walls, reduced material use, and energy savings without compromising durability.

How do PVC-O pipes contribute to environmental sustainability?

PVC-O pipes have a long service life, lower embodied energy compared to alternatives, and integrate recycled materials, reducing the carbon footprint and waste.

What is the expected lifespan of PVC-O pipes?

PVC-O pipes can last over 50 years, reducing the frequency of replacements and environmental impact compared to traditional pipe materials.

Are PVC-O pipes recyclable?

Yes, they are designed for recycling, including compatibility with post-consumer PVC, and they incorporate circular economy principles to reduce landfill waste.